1. Unveiling the Radiance of Chocolate: The Magic of Polycarbonate Chocolate Moulds

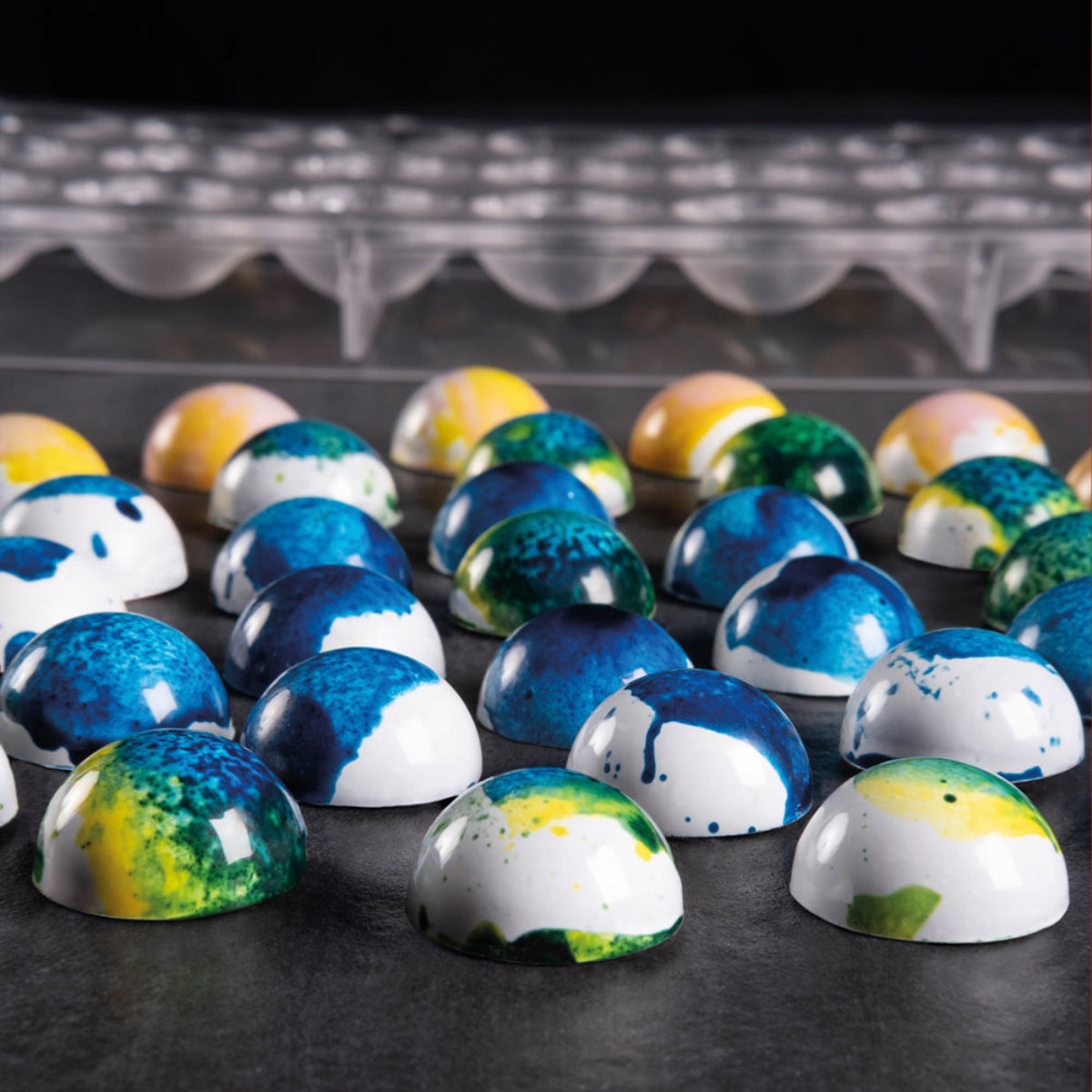

Unlike any other material, Polycarbonate chocolate molds hold an unparalleled ability to illuminate the brilliance of chocolate. By uniformly distributing the heat of tempered chocolate and capitalizing on the transparency of the mold, the controlled cooling process during crystallization becomes a reality. This integral feature of Martellato molds guarantees that your chocolate retains its impeccable shine and texture throughout production.

2. Quality Uncompromised: The Signature of Martellato Moulds

The cornerstone of Martellato molds lies in their unwavering commitment to quality. Melding top-tier materials with a passion for crafting exceptional chocolate, Martellato's offerings stand at the forefront of their category. This devotion to excellence isn't just confined to design and extended to the entire production process. Rigorous testing ensures that every mold that reaches your hands is nothing short of perfection.

3. Crafting for Professionals: Elevating Chocolate Mastery

Understanding that professionals are the driving force behind their success, Martellato places utmost importance on the feedback from those who toil in the culinary labs. Molds designed for professionals must stand up to scrutiny, ensuring optimal crystallization times and facilitating seamless de-molding for heightened productivity and aesthetics. This philosophy is reflected in the meticulous design and rigorous testing each mold undergoes before being introduced to the market.

Secrets to Maximizing the Potential of Polycarbonate Chocolate Moulds

#1 - Cleaning: A Prerequisite for Pristine Results

A meticulously clean mold is the cornerstone of flawless chocolate creations. Eradicate any residues with soft sponges or cloths, avoiding abrasive products that could mar the mold's surface. Limit water temperature during washing to 50/55°C to ensure longevity and opt for mild or specific detergents. Low-lime or demineralized water maintains the mold's luster and integrity.

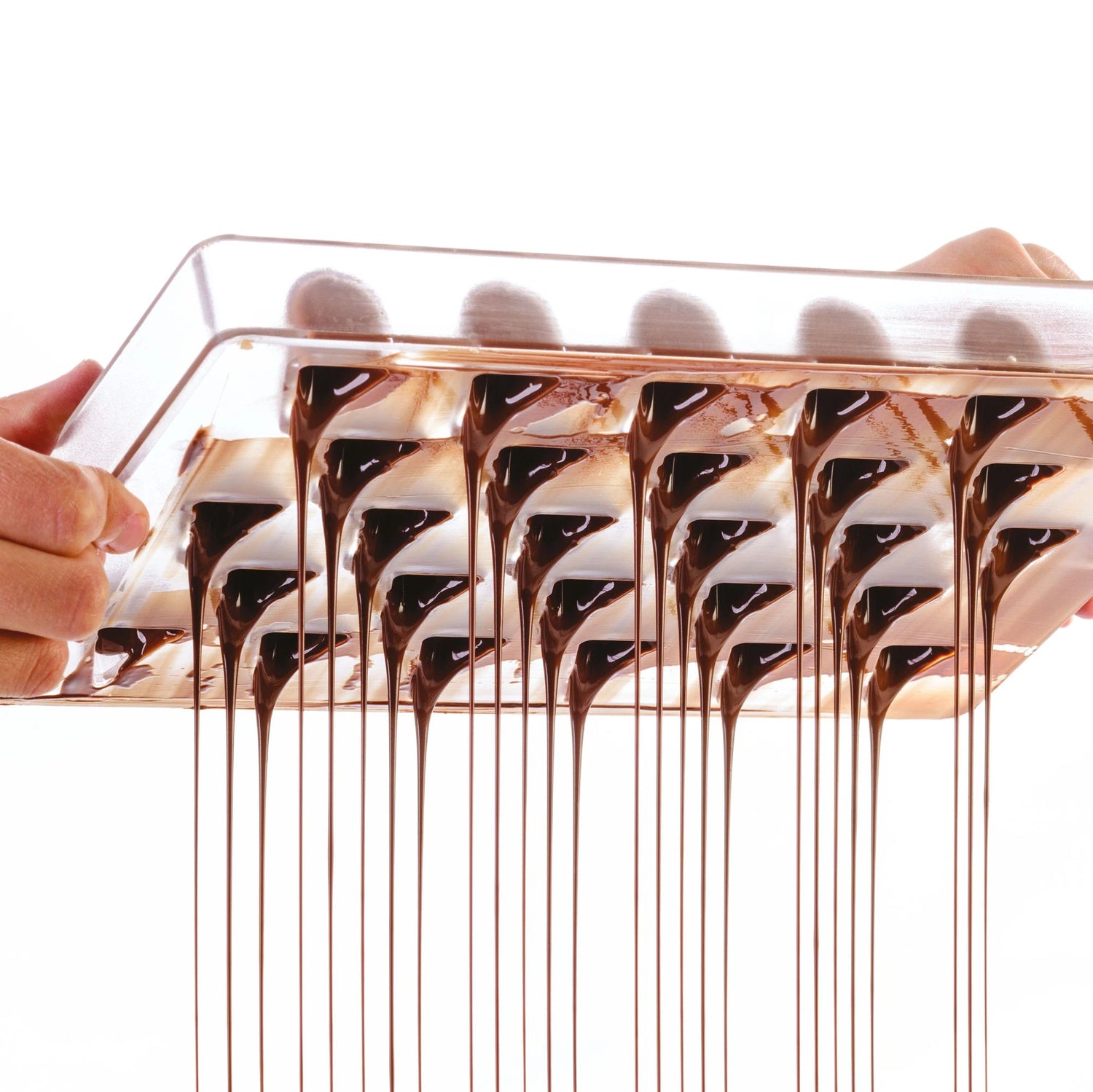

#2 - Tempering: The Art of Perfecting Chocolate

Flawless tempering is a non-negotiable aspect of creating sublime chocolate products. Imperfect tempering leads to surface imperfections, indicating improper butter crystallization. Stirring the chocolate as you work maintains stable cocoa butter crystals. Optimal tempering temperatures differ based on chocolate type: dark (31°C), milk (29°C), and white (28°C). Matching mold temperature with tempered chocolate enhances the glossy finish and texture of the product.

#3 - Working Space: The Crucial Climate for Chocolate Mastery

Creating chocolate wonders demands the right environment. Maintain a room temperature of 18 to 20°C and humidity levels of 55 to 60%. This controlled setting ensures that your chocolate remains in its prime, allowing you to shape your creations precisely.

#4 - Maintenance: Preserving Molds' Lifespan

Gentle maintenance ensures the longevity of your polycarbonate molds. Even if unused, periodic gentle cleanings help retain their quality. Keeping these molds in good condition ensures their continued excellence over the years.

#5 - Conservation: Storing Your Treasures with Care

Post-use, protect your molds from the passage of time. Store them correctly, either covered or within a box, safeguarding against dust accumulation that can harm the mold's surface. Optimal storage involves keeping molds on flat surfaces, away from heat and light sources, and ideally elevated from the ground.So go forth, armed with these five secrets, and embark on a journey to create chocolate wonders that captivate the taste buds and stand as a testament to the harmonious marriage of innovation and tradition that Martellato brings to the world of chocolate craftsmanship.

Discover the Art of Tempering with DigitalMeltinchoc:

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.