In the art of chocolate making, achieving the perfect sheen and snap boils down to one magical yet puzzling word: tempering. It's essential for creating chocolate confections that truly delight—silky smooth with a satisfying crunch. But what exactly goes into tempering chocolate, and what tools are needed for this mélange of alchemy and science? Welcome to an immersive exploration into the intricate world of chocolate tempering tools.

This article unveils the secrets behind the techniques and the equipment necessary to master this craft. Whether you're a budding chocolatier or a seasoned professional, understanding these elements is crucial for elevating your chocolate game.

Table of Contents

-

Understanding Chocolate Tempering

-

Essential Tools and Equipment

-

Techniques and Methods

-

Practical Applications and Tips

-

Industry Insights and Trends

Understanding Chocolate Tempering

Tempering chocolate is more than just melting it down and cooling it off; it's a precise process that aligns the cocoa butter crystals to assure the final product's perfect look and texture. The process involves heating and cooling the chocolate to specific temperatures, a method known for its meticulousness and need for precision. In this section, we will navigate through the fine details of tempering chocolate and understand why it's a must for any chocolate-related creation.

What is Chocolate Tempering?

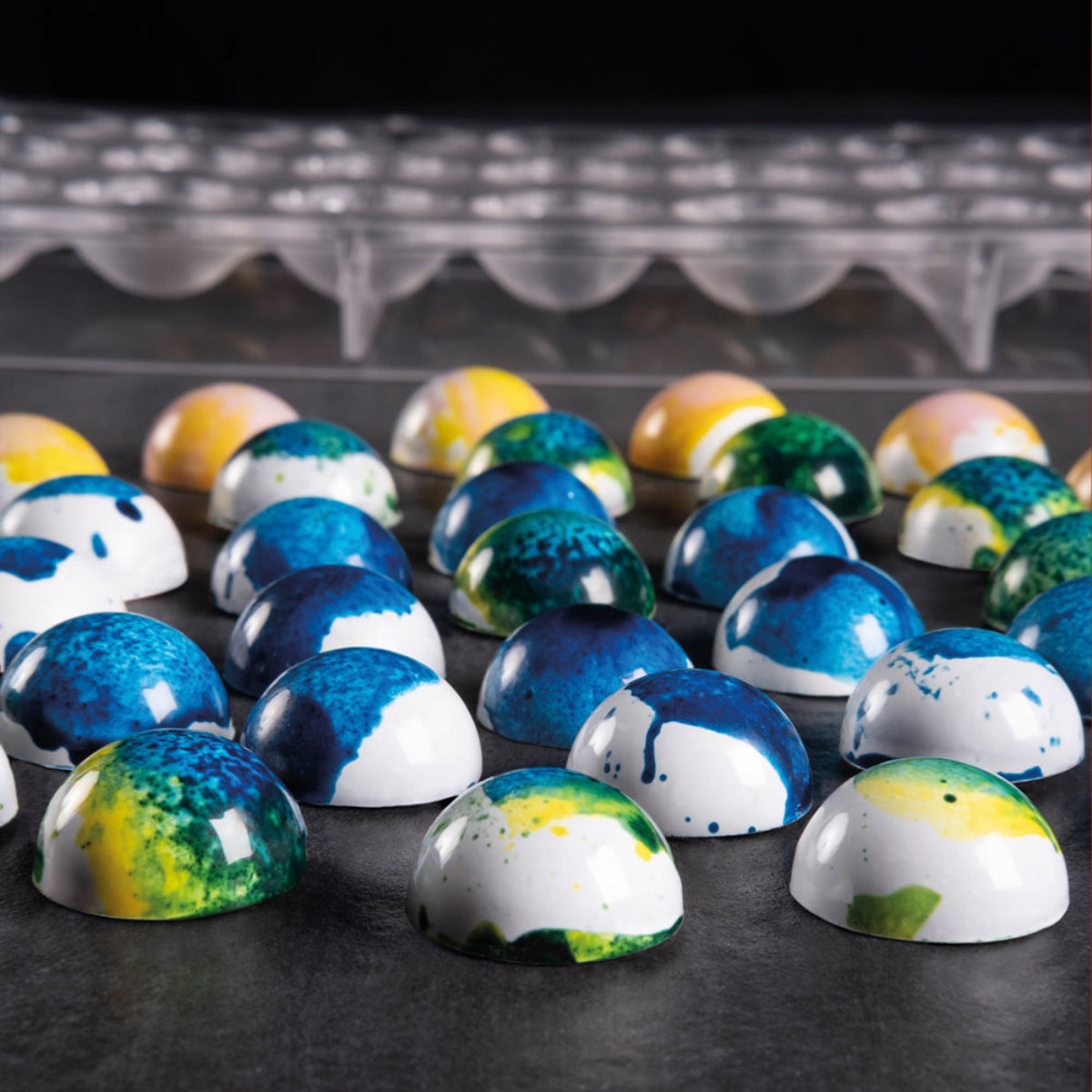

Chocolate tempering is a technique used to pre-crystallize the cocoa butter in chocolate, which gives it the right properties for coating and molding. This results in chocolate that is glossy and firm, with a crisp snap when broken, and it melts smoothly in the mouth. Properly tempered chocolate also contracts slightly as it cools, making it easier to release from molds.

Why is Tempering Important?

Without tempering, chocolate can become dull and soft, even develop unsightly white spots known as bloom. These arise from either cocoa butter rising to the surface or sugar blooming due to moisture. Thus, tempering is not just about aesthetics; it significantly impacts flavor delivery and texture.

Essential Tools and Equipment

The journey of tempering chocolate requires an ensemble of tools designed to achieve precision and efficiency. From simple home kitchen tools to advanced professional equipment, each plays a vital role in ensuring successful tempering.

Tools for the Home Chocolatier

-

Marble Slabs:

The marble slab is a classic tool for tempering, known for its ability to cool chocolate evenly. It's essential for the technique called tabling, where melted chocolate is spread and scraped over the slab to cool uniformly. -

Thermometers:

Accurate temperature readings are crucial for tempering. A digital thermometer makes it easy to track chocolate's temperature at various stages of the process. -

Spatulas and Scrapers:

Used for stirring and spreading chocolate across surfaces, these tools help maintain consistency during tempering.

Professional Equipment

-

Tempering Machines:

Brands offer advanced tempering machines that automate the process. These machines melt and cool chocolate to precise temperatures, ideal for high-volume production environments. -

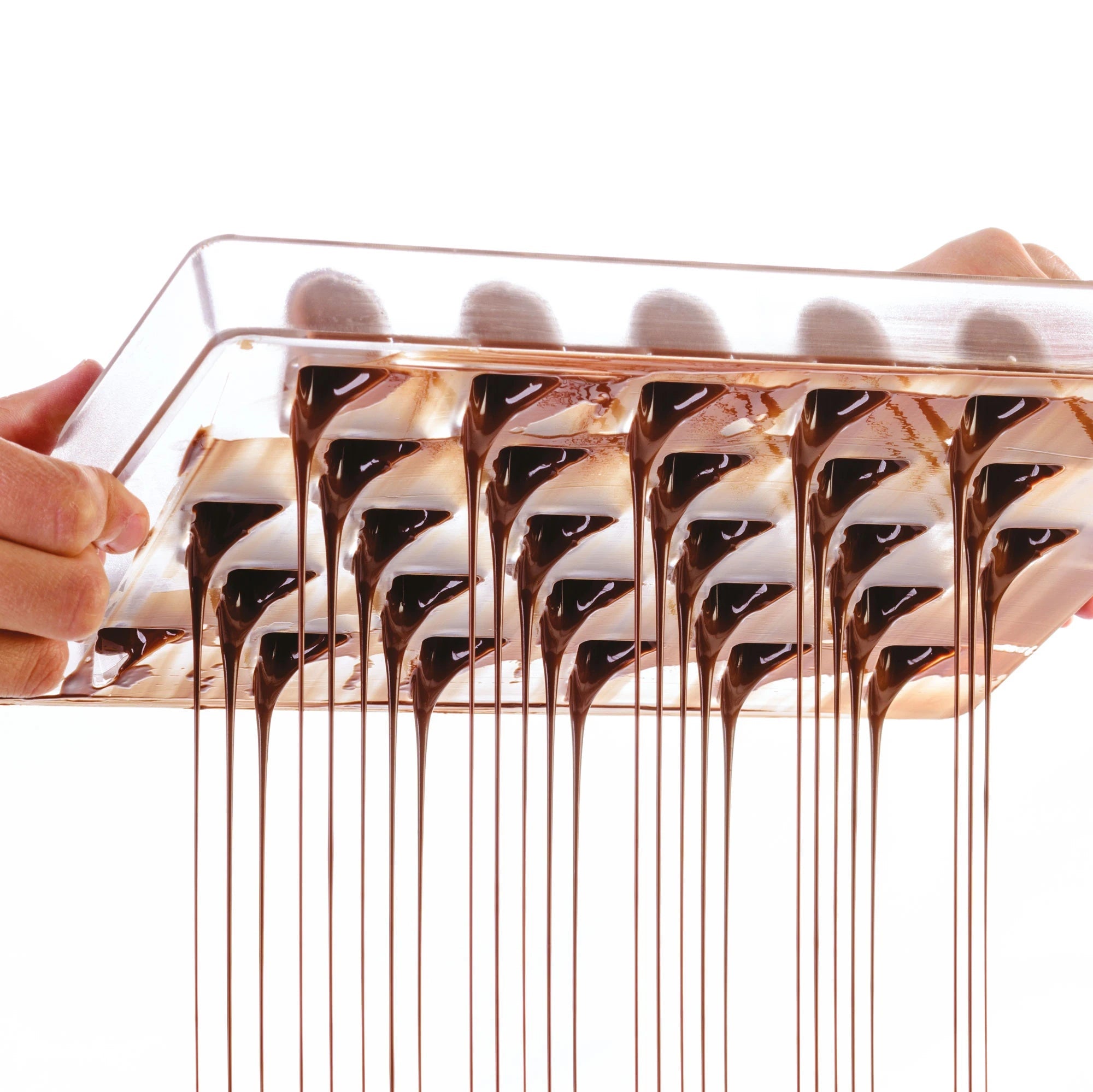

Chocolate Enrobing Belts:

These are specialized pieces of equipment designed to coat confections with a layer of chocolate, ensuring an even and professional finish. -

Tabletop Chocolate Melters:

Available in various sizes, these machines are perfect for melting and maintaining chocolate at a constant, desired temperature.

Techniques and Methods

Tempering isn't a one-size-fits-all process. Various techniques cater to different scale operations and preferences. Here, we dissect common tempering methods and how tools play a pivotal role in each.

The Seeding Method

In the seeding method, a portion of tempered chocolate is added to melted chocolate to initiate crystallization. This technique is popular for its simplicity and is widely used by home chocolatiers.

-

Best Practices: Begin by melting chocolate to 118°F/48°C, then adding seed chocolate at 89°F/32°C for dark variants. This method requires constant stirring and maintaining a steady temperature, achievable with a reliable thermometer.

The Tabling Method

The tabling method involves pouring melted chocolate onto a marble surface and repeatedly spreading it until it cools to the right temperature.

-

Key Tools: A marble slab and metal scraper are essential for this method. The goal is to create a homogeneous spread that ensures even cooling and crystallization.

The Block Seeding Method

In this method, large chunks of solid tempered chocolate are added to melted chocolate to bring down the temperature.

-

Application: This technique is ideal for larger batches, commonly employed in bouts of professional chocolate production.

Practical Applications and Tips

Implementing tempering techniques in real-world scenarios can significantly influence the quality of final products. Here are practical tips and insights to help you get the best results.

Tips for Small Batches

-

Use a metal bowl, as advised by professionals to speed up the tempering process by spreading out the heat.

-

Stir frequently to ensure consistent temperature throughout the batch.

Considerations for Large-Scale Production

-

Automated tempering machines from reputed brands can offer precise control and higher throughput.

-

Check for features such as programmable settings and automatic shut-offs to prevent overheating.

Common Mistakes and How to Avoid Them

-

Temperature Fluctuations: Always use a reliable thermometer. Keep chocolate well-insulated to maintain temperatures.

-

Humidity Control: Chocolate is sensitive to moisture, which can cause blooming. Ensure a dry environment during the tempering process.

Advanced Relationship Implications

Technological advancements and industry trends continue to shape the chocolate tempering landscape, introducing innovative tools and techniques.

Industry Trends and Technological Advances

-

The rise of bean-to-bar chocolate production has spurred innovation in temper machines, focusing on ease of use and precise temperature control.

-

Eco-friendly practices are gaining priority, encouraging the development of energy-efficient tempering solutions.

Environmental and Regional Considerations

-

Regional climate can impact tempering conditions, necessitating tweaks in methods and machinery settings. Chocolatiers in humid areas might require dehumidifiers to maintain optimal conditions.

Conclusion

In wrapping up this exploration into chocolate tempering, it's evident that the tools and techniques are deeply intertwined with both the art and science of chocolate making. From the tactile tabling method on a marble slab to sophisticated tempering machines, each tool brings its unique flair to the process. Mastery of these tools can lead to truly exquisite chocolate creations, shimmering and snapping in all their glory.

As chocolate-making technology and techniques continue to evolve, staying informed through industry reports and studies by experts like the team at the Selmi Group ensures that chocolatiers are always at the forefront of innovation and creativity. Embrace these advancements, stay curious, and may your chocolate creations be ever glossy and delightful.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.