Starting a chocolate business requires thoughtful investment in the right tools and equipment. Beyond just enabling production, proper equipment ensures consistent quality, efficient operations, and safe food handling. Let's explore the essential equipment you'll need at every stage of chocolate production.

Temperature Control Equipment

Temperature management is perhaps the most critical aspect of chocolate work, affecting everything from texture to shelf life.

Tempering Machines

Proper chocolate crystallization requires precise temperature control, making tempering machines indispensable for any serious chocolate business. These come in several formats:

A tabletop continuous tempering machine (2-5kg capacity) serves as the backbone of small to medium chocolate operations. These machines maintain chocolate at precise working temperatures while constantly stirring to promote proper crystallization. Models like the Revolation V by Chocovision ($1,200-1,800) or ChocoMelter by Selmi ($3,500-5,000) represent entry-level professional options that can process enough chocolate for about 300-500 bonbons per batch.

For larger operations, wheel tempering machines offer increased capacity (10-50kg) and more precise temperature control, often with programmable temperature curves for different chocolate types. The temperature precision of ±0.5°C these machines provide ensures the formation of stable Type V crystals that give chocolate its snap, shine, and proper mouthfeel.

The investment in a quality tempering machine directly correlates with product consistency and production efficiency. While manual tempering is possible, the time saved and consistency gained from a dedicated machine typically pays for itself within months for a commercial operation.

Warming Cabinets

Chocolate moulds must be at the optimal temperature before being filled with tempered chocolate. A warming cabinet maintains moulds at 28-30°C, preventing temperature shock when chocolate is introduced.

Professional warming cabinets include features like digital temperature controls, multiple shelves for organizing different mould types, and forced-air circulation to eliminate hot spots. Even small models that accommodate 10-15 moulds (approximately $500-900) dramatically improve product consistency compared to makeshift warming methods.

For operations filling multiple moulds in sequence, a warming cabinet prevents the first-filled moulds from setting too quickly compared to later ones, ensuring uniform working time across a production batch.

Production Equipment

Melters and Bain-Maries

Before tempering, chocolate must be melted completely to eliminate all existing crystal structures. Dedicated chocolate melters provide gentle heating that prevents scorching:

Double-boiler style melters with water jackets offer even heat distribution and temperature control between 30-60°C. Professional models include features like automatic water refilling and precise digital controls.

For operations working with multiple chocolate types simultaneously, a melting station with 2-4 separate melting pots allows you to work efficiently with dark, milk, white, and colored chocolates without cross-contamination.

The melting capacity should align with your production volume—for a small artisanal operation producing 5-10kg of chocolates daily, a 5-7kg melter represents sufficient capacity without excessive energy use.

Enrobing Equipment

For chocolate-coated products like truffles, cookies, or nuts, an enrobing system dramatically increases production efficiency:

Entry-level enrobing machines feature a conveyor belt that passes products through a curtain of tempered chocolate, with adjustable flow controls and vibration systems to remove excess coating. Small commercial enrobers (12-24 inches wide) start around $4,000-7,000 but can increase production capacity by 5-10 times compared to hand-dipping.

The return on investment calculation for enrobing equipment should consider both increased production capacity and improved product consistency. Many chocolate businesses report that enrobing equipment pays for itself within 6-12 months through labor savings alone.

For businesses not ready for a full enrobing line, a chocolate dipping fork set ($20-50) with specialized shapes for different coating techniques represents an essential interim tool.

Moulds and Frames

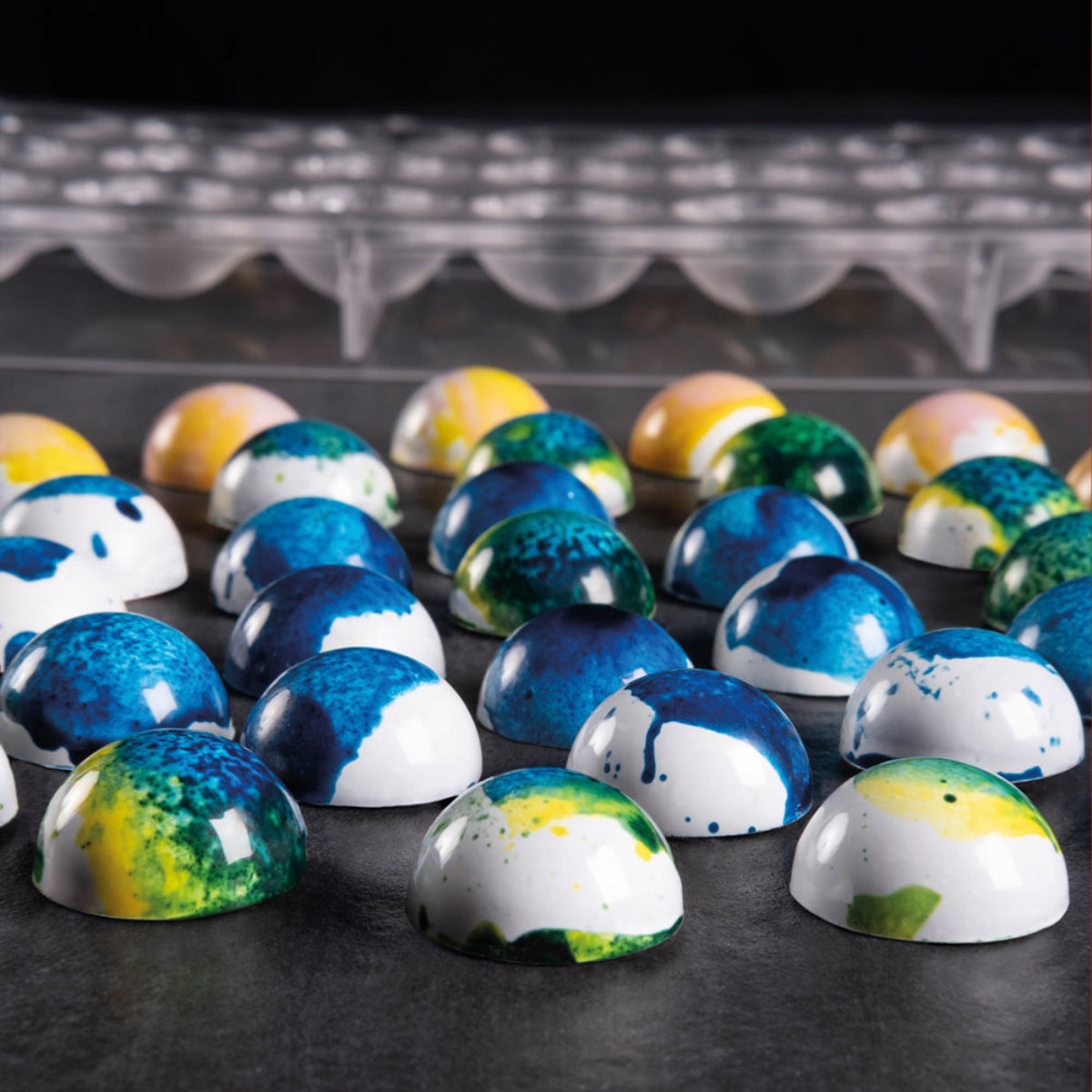

Moulds determine your product appearance and significantly impact both production efficiency and chocolate release:

Professional polycarbonate moulds ($30-70 each) represent the industry standard, offering excellent release properties, durability for thousands of uses, and the high-gloss finish consumers associate with quality chocolates. A starting inventory of 10-15 professional moulds allows for a diverse product line while managing production scheduling.

For chocolate bars, adjustable frames allow custom sizes and thicknesses. A set of professional bar frames with adjustable dividers ($200-400) provides flexibility to create everything from large sharing bars to miniature tasting squares.

Specialty moulds for seasonal items should be viewed as marketing investments rather than just production tools. Distinctive shaped chocolates for holidays or events can command premium pricing and generate social media attention.

Ingredient Preparation Equipment

Mixers and Food Processors

Preparing fillings and inclusions requires dedicated equipment for consistent results:

A commercial planetary mixer (5-7 quart) handles ganaches, caramels, and praline pastes with the power needed for proper incorporation. Professional models with variable speed controls and multiple attachments ($800-1,500) provide the versatility needed for diverse product lines.

For nut-based fillings and inclusions, a dedicated food processor capable of achieving ultra-smooth textures is essential. Commercial models with powerful motors ($300-700) can process nuts to the fine consistency needed for smooth praline fillings.

To prevent cross-contamination, especially with allergen concerns, many chocolate businesses maintain separate mixing equipment for different ingredient categories.

Precision Scales

Chocolate work demands exceptional accuracy in measuring ingredients:

A digital scale with 0.1g precision for ingredient measuring ensures consistency in ganaches and fillings. Professional models with calibration capabilities and tare functions ($150-300) should be viewed as quality control equipment rather than just measuring tools.

For high-volume ingredient measuring, a separate bench scale with 1-5kg capacity provides efficiency without sacrificing accuracy.

Portion control scales for filling chocolates help maintain consistent weight across products, important for both quality consistency and proper costing calculations.

Specialized Tools

Airbrushing Equipment

For decorated chocolate work, a dedicated chocolate airbrush system allows precise application of colored cocoa butter:

Professional food-grade airbrush systems with compressors ($200-500) should be reserved exclusively for chocolate work, as cross-contamination from other uses can affect flavor and safety.

A complete system includes multiple needle sizes for different application techniques, from fine detail work to broader coverage. The investment in quality equipment directly translates to the precision and durability of decorative elements.

For businesses focusing on premium visual presentation, a set of colored cocoa butters ($15-25 per color) complements the airbrush equipment and expands decorative possibilities.

Chocolate Guitars and Cutters

For cutting ganaches, caramels, and other fillings with precision:

A professional chocolate guitar ($250-500)—a frame with parallel cutting wires—allows entire sheets of filling to be cut to identical sizes simultaneously. This specialized tool dramatically increases production efficiency and product consistency for filled chocolates.

For operations not ready for a guitar, a set of professional ganache cutters in graduated sizes ($75-150) provides an alternative with lower initial investment.

Heated cutting tools for clean edges on sensitive fillings represent specialized equipment that elevates product appearance beyond what most competitors can achieve.

Storage and Aging Equipment

Refrigeration

Specialized chocolate refrigeration differs from standard commercial refrigeration:

Chocolate-specific refrigeration maintains temperature between 10-13°C with humidity control below 55% to prevent condensation issues. These specialized units ($2,000-5,000) represent a significant advantage over standard refrigeration, which often introduces moisture that damages chocolate.

For smaller operations, wine refrigerators reprogrammed to chocolate-appropriate temperatures can serve as an acceptable alternative, as they typically offer better humidity control than standard refrigeration.

The staging capacity of refrigeration should accommodate at least a full day's production to prevent workflow bottlenecks.

Crystallization Chambers

For filled chocolates that benefit from aging:

Controlled environment chambers maintain consistent temperature and humidity during the critical 12-24 hour period when filled chocolates stabilize. Professional units with digital controls ($1,500-3,000) dramatically improve shelf life and texture development compared to open-air aging.

The capacity calculation should consider your production cycle—for a business producing chocolates daily, chamber capacity for 2-3 days of production provides operational flexibility.

Packaging Equipment

Heat Sealers

Proper packaging extends shelf life and maintains product quality:

Impulse heat sealers for closing bags and wrappers provide hermetic seals that protect chocolates from humidity and odor absorption. Professional models with temperature control and seal width options ($200-500) ensure packaging integrity without damaging heat-sensitive materials.

For businesses using flow-wrap packaging for bars, a semi-automatic bar wrapper ($3,000-7,000) increases production speed from 30-50 bars per hour to 300-500, while significantly improving presentation consistency.

Labeling Equipment

Professional presentation requires consistent label application:

A semi-automatic label applicator for boxes and packages ensures straight, bubble-free application that enhances perceived product value. Even basic models ($300-700) provide significant advantages over hand application for businesses producing more than 100 packages daily.

For date coding and lot tracking, a dedicated thermal printer ($200-400) prints professional, consistent information necessary for retail distribution and inventory management.

Quality Control Equipment

Texture Analysis Tools

Measuring product consistency objectively improves quality control:

A snap gauge for testing chocolate temper provides objective measurement of crystallization quality. Professional models ($300-500) quantify the breaking point of chocolate, eliminating guesswork about proper tempering.

For filled chocolates, a penetrometer measures filling consistency and provides numerical data for quality control documentation. This specialized tool ($200-400) helps detect subtle variations in texture that might affect customer experience.

Moisture Testing

Controlling moisture content dramatically affects chocolate shelf life:

A digital moisture analyzer for testing fillings and inclusions helps prevent water activity issues that lead to sugar bloom. Professional units ($800-1,500) provide precise measurements that correlate directly with product stability and shelf life.

For businesses developing new recipes, this equipment helps predict potential shelf-life issues before they occur in distributed products.

Safety and Sanitation Equipment

Cleaning Systems

Chocolate-specific cleaning requirements demand specialized equipment:

A high-pressure hot water system for cleaning equipment and surfaces removes chocolate residue without excessive chemical use. Compact professional systems ($700-1,500) dramatically reduce cleaning time while improving sanitation results.

For mould cleaning, ultrasonic cleaners specifically sized for chocolate moulds ($300-800) remove residue from intricate details without damaging surfaces. The time saved in cleaning complex moulds often pays for this equipment within months.

Food Safety Monitoring

Regulatory compliance requires proper monitoring tools:

A digital temperature logging system for refrigeration and production areas provides documentation for food safety compliance. Modern systems ($200-500) offer continuous monitoring with alerts for temperature excursions.

For surface testing, ATP swab systems ($300 for starter kit) provide objective verification of cleaning effectiveness, particularly important for allergen control programs.

Starting Small: Essential Equipment for Beginners

For those beginning with limited capital, prioritize these foundational pieces:

-

A small tabletop tempering machine (2-3kg capacity)

-

Professional-grade polycarbonate moulds (5-8 designs)

-

Digital scale with 0.1g precision

-

Commercial food processor for fillings

-

Basic chocolate tool kit (dipping forks, scrapers, thermometer)

-

Appropriate refrigeration with humidity control

This starter package ($2,000-3,500) enables production of professional-quality chocolates while building capital for expansion. As production volumes increase, prioritize equipment that addresses the most significant workflow bottlenecks or quality control challenges.

Equipment Scaling Strategy

As your chocolate business grows, equipment investments should follow a strategic progression:

Early Growth Phase (Years 1-2)

Prioritize equipment that directly impacts product quality and consistency—tempering machines, professional moulds, and precise measurement tools. Customer perception of quality establishes your market position and justifies premium pricing.

Expansion Phase (Years 2-3)

Focus on production efficiency with semi-automated equipment like enrobers, chocolate depositors, and packaging systems. These investments increase production capacity without proportional labor cost increases.

Maturity Phase (Years 3+)

Invest in specialized equipment for product differentiation—airbrush systems, transfer sheet capabilities, and custom mould development. These tools enable unique offerings that distinguish your brand in a competitive marketplace.

Final Considerations

When building your equipment inventory, consider these additional factors:

Power Requirements

Professional chocolate equipment often requires specialized electrical service. Verify your production space can accommodate the voltage and amperage needs of larger equipment before purchasing.

Maintenance Contracts

For critical equipment like tempering machines and refrigeration, service contracts with 24-48 hour response times protect against catastrophic production interruptions.

Training Support

Equipment suppliers offering comprehensive training and ongoing technical support provide value beyond the physical equipment. This support is particularly valuable when implementing new production techniques.

Zucchero Canada's specialized chocolate equipment represents professional-grade options suited to various business scales, from artisanal to industrial production. Their technical support and industry expertise provide valuable guidance for businesses at all stages of development.

By thoughtfully building your equipment inventory with quality tools appropriate to your production volume and product line, you create the foundation for chocolate products that delight customers while maintaining efficient production processes. Each equipment investment should serve both your immediate production needs and your long-term business vision.

Dejar un comentario

Todos los comentarios se revisan antes de su publicación.

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.