A chocolate melter machine is an essential tool for chocolatiers, bakers, and anyone who needs to melt chocolate efficiently and consistently. Choosing the right chocolate melter can significantly influence the texture, shine, and quality of your melted chocolate. In this guide, we’ll walk you through the key features, comparisons, and factors to consider when selecting the right chocolate melter for your needs, helping you balance efficiency, functionality, and price.

Understanding Chocolate Melter Machines

A chocolate melter uses precise, controlled heat to melt large or small quantities of chocolate evenly. This allows you to avoid common pitfalls such as burning or seizing, which can happen with improper methods. The primary types of chocolate melters include electric melters, water bath models (Bain-Marie), and commercial-grade melters that serve different needs and scales of operation.

Electric melters provide convenience with automated controls, while Bain-Marie systems offer indirect heating and prevent overheating. Understanding these types is crucial for choosing the best model that suits your chocolatier tasks—whether working at home or in a professional setting.

Key Features to Look for in a Chocolate Melter

Precise Temperature Control

Precise temperature control is critical in chocolate melting because the delicate balance between heat and chocolate structure affects quality. Machines with built-in thermostat settings or digital controls allow for consistent melted chocolate without the risk of burning. Ensuring that your chocolate stays within 30-32°C (86-90°F) for dark chocolate and lower for milk or white chocolates is essential.

Table: Ideal Chocolate Melting Temperatures by Type

|

Chocolate Type |

Melting Temperature Range |

|

Dark Chocolate |

30-32°C (86-90°F) |

|

Milk Chocolate |

28-30°C (82-86°F) |

|

White Chocolate |

27-28°C (80-82°F) |

Overheat Protection

Machines with overheat protection prevent chocolate from scorching while ensuring that the heating element maintains efficiency. Overheating chocolate can cause it to seize, leading to waste of ingredients and negatively impacting texture. Overheat protection mechanisms keep chocolate at the right temperature once it reaches the desired point.

Heating Methods: Direct Heat vs. Indirect Heat

Chocolate melters use either direct heating or a Bain-Marie system (indirect heat). Direct heating is faster but risks burning if not controlled properly, while Bain-Marie/double boiler systems protect against overheating and maintain steady, gentle heat. For beginners, indirect heat solutions provide more control and reduce chances of error.

Capacity: Matching Your Melter to Your Needs

Capacity is an important consideration when choosing a chocolate melter as it determines how much chocolate can be melted at once. Smaller melters typically handle 1-2 lbs. and are perfect for hobbyists or small batches, whereas larger ones can handle up to 10+ lbs., ideal for professionals and commercial kitchens mass-producing confectionaries.

The right capacity ensures you aren't underproducing or overworking your machine during use.

If you work with different types of chocolate simultaneously, consider dual-tank melters. These machines allow you to melt two separate batches of chocolates with dedicated temperature controls, providing greater flexibility.

Temperature Control: Essential for Consistent Melting

Temperature control determines the quality and consistency of melted chocolate. An accurate thermostat gives you full control without needing to repeatedly check or stir the chocolate, allowing for reliability throughout the process.

Melters with multi-zone temperature control can heat two different zones at different temperatures, ideal for complex chocolate work.

When temping chocolate, achieving precision is the key to beautifully glossy, tempered chocolate.

For example, dark chocolate should be around 31-32°C with a slight variation depending on the type of chocolate. Accurate temperature regulation ensures the chocolate doesn't cool too fast or maintain too high temperatures that could impact crystallization.

Materials of Chocolate Melter: Durability and Ease of Use

A stainless steel basin is one of the most durable and easy-to-clean options for a chocolate melter. Stainless steel is highly conductive, distributes heat evenly, and is durable enough to withstand constant use.

Additionally, BPA-free, food-grade plastics are commonly used for exterior housing but avoid inferior quality materials that may degrade over time.

Having a non-stick interior minimizes chocolate build-up, reduces burning risks, and makes post-session cleanups easier. A machine built with durable materials ensures not only longevity but also ease of maintenance after each use.

Maintenance and Cleaning of a Chocolate Melter

Chocolatiers know that ease of cleaning directly correlates with their machine's functionality and lifespan. Regular maintenance, such as cleaning the internal components and ensuring the heating elements are free of chocolate residue, increases the efficiency and durability of your machine. Machines with easily detachable parts, such as the removable basin or scrapers, are ideal for quick and thorough cleaning.

If the machine’s interior is dishwasher-safe, it removes the hassle of manual scrubbing. Always check the manufacturer’s guidelines on how best to clean the machine without damaging electrical components.

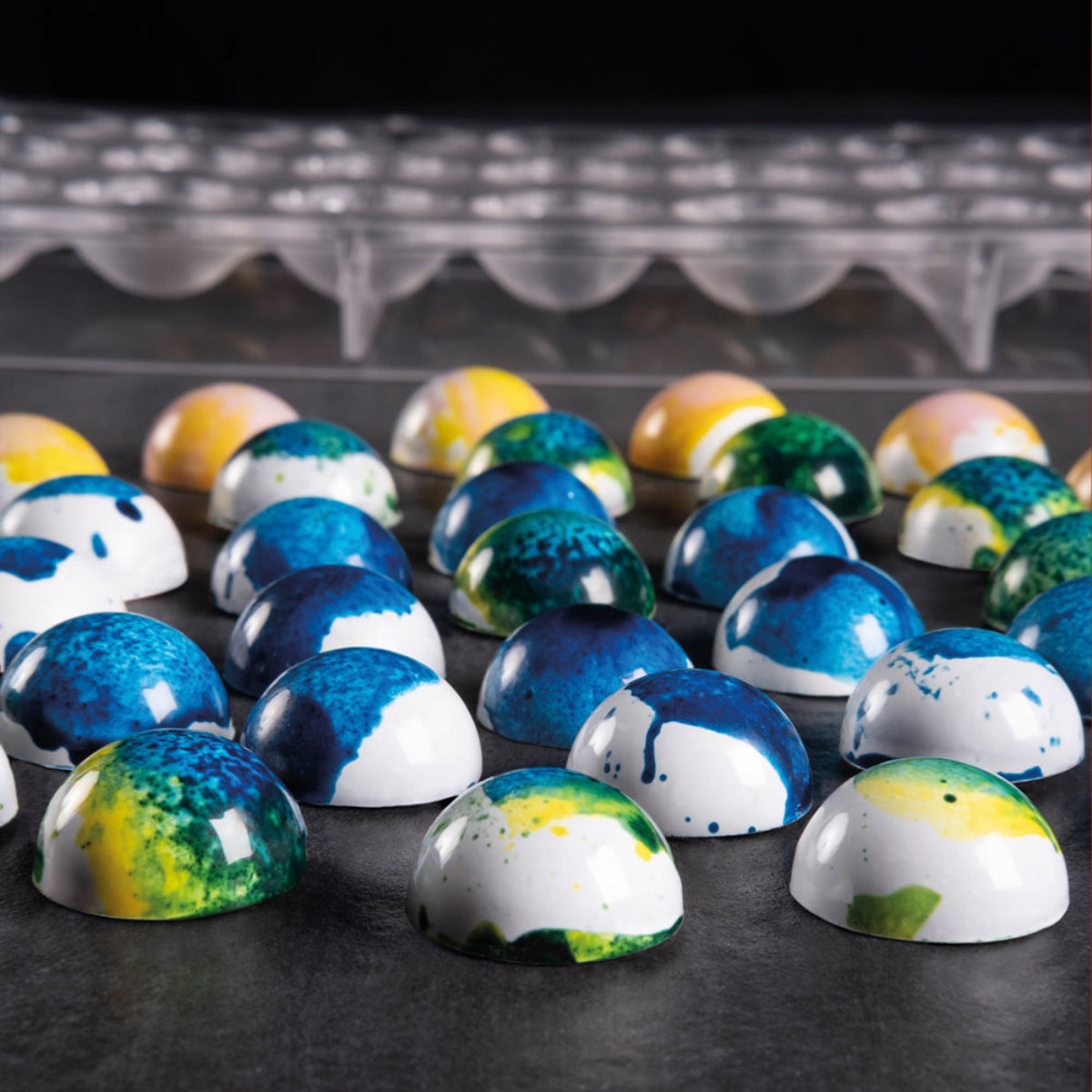

Applications: What Can You Use a Chocolate Melter For?

Chocolate melters are versatile tools used in different stages of chocolate confectionery production. You can melt chocolate to:

-

Prepare molds for perfect chocolates with a shiny finish.

-

Enrobing or coating: Melted chocolate is used to create glossy, smooth coatings for cakes, truffles, and other confections.

-

Dipping fruits or snacks, such as strawberries and pretzels, creates elegant, visually appealing treats.

The right chocolate melter ensures steady heat, which is critical for the fluidity needed in the molding, enrobing, or dipping stages.

Choosing the Right Melter Based on Your Setting

Not all melters are built for all settings. Home users will likely benefit from compact electric melters with precise controls, while artisanal chocolatiers or businesses might need high-capacity melters to keep up with large-scale chocolate production. Commercial melters handle bulky volumes with digital precision, whereas small tabletop versions serve perfectly for hobbyists practicing at home.

Beginner chocolatiers should consider compact, easy-to-use melters with built-in temperature presets, while more experienced professionals might need more advanced machines containing precise temperature settings and robust features.

Brand Comparison: The Best Chocolate Melter Brands on the Market

Widely respected among chocolatiers, brands like ChocoVision, Selmi, and Wilton offer options in the premium and affordable segments:

-

ChocoVision: Known for its precision and advanced features like automatic tempering, perfect for higher-end operations.

-

Selmi: An industry-leader for large-scale production, offering professional machines with high-end specifications.

-

Wilton: A more affordable option popular with hobbyists. It offers great entry-level melters for occasional use with basic features.

When choosing a brand, focus on factors like the scale of your production, budget, and the specific features you need.

Price vs. Features: How to Get the Best Value for Money

Balancing features with price is essential when selecting a chocolate melter. Premium machines often come with added benefits such as digital displays, dual tanks for handling multiple chocolate types, and larger batch capacities.

List: Key Features Worth Paying Extra For

-

Precise Digital Temperature Control

-

Multi-zone Heating

-

Detachable and Dishwasher-Safe Parts

On the other hand, hobbyists or small-scale users may find more affordable machines that provide good value but sacrifice a few premium features unnecessary for smaller projects.

Maximizing Performance: Tips for Optimal Use

To get the best performance from your chocolate melter, continuously monitor the temperature, stir regularly, and ensure that you pre-melt the chocolate before introducing it to the machine. Consistent use of temperature presets for different types of chocolate helps you avoid overheating and maintain the chocolate's smooth consistency.

Durability: How to Ensure Long-Lasting Use of Your Chocolate Melter

Several factors affect the longevity of a chocolate melter, including maintenance practices and the quality of materials used in manufacturing. Machines made with stainless steel and non-stick surfaces last longer and are easier to clean. Regular inspection and cleaning of the interior and heating elements extend a machine's lifespan and prevent common breakdowns.

Safety Features To Consider

Safety is important, especially if you plan on using the chocolate melter extensively. Automatic shut-off mechanisms ensure that the machine doesn’t overheat or run unattended for too long, while insulated handles and external parts keep the machine's surface safe to the touch, reducing the risk of burns. Machines with child-safety locks are also recommended for homes with children.

Final Recommendations: Choosing the Best Chocolate Melter

Selecting the best chocolate melter depends on your specific needs, whether you’re a beginner or professional chocolatier. Evaluate based on capacity, material durability, temperature control, and special features relating to safety and ease of cleaning. By focusing on quality brands, proper maintenance, and matching your melter’s functionalities with your production needs, you’re sure to find the right match for perfect, consistently melted chocolate every time.

Dejar un comentario

Todos los comentarios se revisan antes de su publicación.

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.