Key Takeaways

- Conching chocolate is a crucial refining process that transforms rough chocolate mass into smooth, flavorful finished chocolate

- The process was invented in 1879 by Swiss chocolatier Rodolphe Lindt

- Conching develops flavor by reducing acidity and bitterness while enhancing desirable flavor notes

- It improves texture by breaking down particles and distributing cocoa butter evenly

- Conching times typically range from 6-24 hours for commercial chocolate to 72+ hours for premium products

- For quality chocolate supplies for all your baking needs, visit Zucchero Canada

When you bite into a smooth, melt-in-your-mouth piece of chocolate, you're experiencing the results of a process that has been perfected over more than a century: conching. But what exactly is conching chocolate, and why is it so important to creating the silky-smooth texture and complex flavor profile of fine chocolate? Let's explore this fascinating aspect of chocolate production that transforms rough chocolate mass into the delectable treat we all know and love.

The History of Conching Chocolate

The story of conching begins in 1879 with Swiss chocolatier Rodolphe Lindt, who made a revolutionary discovery—some say by accident. Legend has it that Lindt left a mixing machine running over a weekend, and upon returning, found that the chocolate had transformed dramatically in both texture and taste.

Prior to this discovery, chocolate had a gritty, coarse texture and an astringent flavor profile. Early chocolate was primarily consumed as a beverage because it wasn't pleasant to eat in solid form. Lindt's accidental discovery changed chocolate forever, creating what he called "chocolat fondant" (melting chocolate).

Lindt called his machine a "conche" because its shape resembled a conch shell. This invention revolutionized chocolate manufacturing and set a new standard for quality. The Lindt company, which still bears his name today, became famous for its smooth chocolate, and competitors scrambled to develop their own conching methods.

This technological breakthrough was so valuable that when Rudolph Sprüngli acquired Lindt's factory in 1899, he reportedly paid an extraordinary sum—1.5 million Swiss francs (equivalent to many millions in today's money)—largely for the secret of the conching process.

What Exactly is Conching?

Conching chocolate is a prolonged mixing, agitating, and aeration process that's performed after the initial grinding of cocoa nibs and mixing with sugar and other ingredients. It's essentially a controlled mechanical kneading of chocolate mass over many hours—sometimes days—at controlled temperatures.

The name "conche" comes from the shell-shaped vessels originally used in the process. During conching, several crucial transformations occur simultaneously:

- Physical transformation: The chocolate particles are reduced in size and coated with cocoa butter, creating a smoother texture.

- Chemical transformation: Volatile acids evaporate, and beneficial flavor compounds develop through oxidation and other chemical reactions.

- Moisture reduction: The chocolate's moisture content decreases, which helps improve shelf life and texture.

- Emulsification: The fat phase (cocoa butter) becomes evenly distributed throughout the chocolate mass.

The process is both an art and a science—a delicate balance of time, temperature, and agitation that varies depending on the desired end product.

The Conching Process Explained

The conching process is a critical step in chocolate manufacturing that transforms raw cocoa into the smooth, flavorful chocolate we know and love. During conching, specialized machinery redistributes the flavor compounds found in dry cocoa particles, effectively transferring these essential taste elements into the chocolate's fat phase.

Temperature control during the chocolate conching process is a critical factor that directly impacts both processing time and the final flavor profile of different chocolate types. Understanding optimal conching temperatures is essential for achieving the distinctive taste characteristics that define high-quality chocolate products.

The ideal conching temperature varies significantly depending on the type of chocolate being processed:

Milk Chocolate Conching Temperature: Milk chocolate requires the most delicate temperature control, typically maintained around 49°C (120°F). This lower temperature preserves the delicate dairy components while still allowing proper flavor development.

Dark Chocolate Conching Temperature: Dark chocolate can withstand much higher temperatures, often processed at up to 82°C (180°F). This elevated temperature range helps develop the complex flavor compounds that give dark chocolate its characteristic intensity.

Step 1: Initial Mixing

The conching process begins after chocolate ingredients (cocoa mass, sugar, additional cocoa butter, and possibly milk powder) have been mixed and refined to reduce particle size. This initial mixture, though fine in particle size, is still rough in texture and harsh in flavor.

When this mixture enters the conche, it's typically a dry, crumbly mass. The conche's mechanical action—through paddles, rollers, or scraping blades—begins to work this mass continuously.

Step 2: Dry Conching Phase

During the early stage of conching, the chocolate mass is still relatively dry. This phase, sometimes called "dry conching," is when much of the moisture and volatile acids are removed from the chocolate.

The friction and aeration during this phase help to:

- Remove unwanted volatile compounds

- Reduce acidity

- Begin oxidizing certain flavor precursors

- Start the process of coating particles with fat

This phase can last from a few hours to several hours, depending on the recipe and desired outcome.

Step 3: Paste Phase

As conching continues, the chocolate begins to warm up from friction, and the cocoa butter starts to coat the solid particles more effectively. The mass transitions from a dry, crumbly texture to a thicker paste.

During this phase:

- Particles become increasingly coated with fat

- Flavor continues to develop

- Moisture levels continue to decrease

- The chocolate becomes more homogeneous

Step 4: Liquid Phase

In the final stage of conching, additional cocoa butter or lecithin might be added to achieve the desired viscosity. The chocolate now takes on the smooth, flowing consistency associated with finished chocolate.

This phase is crucial for:

- Final texture refinement

- Complete emulsification

- Final flavor development

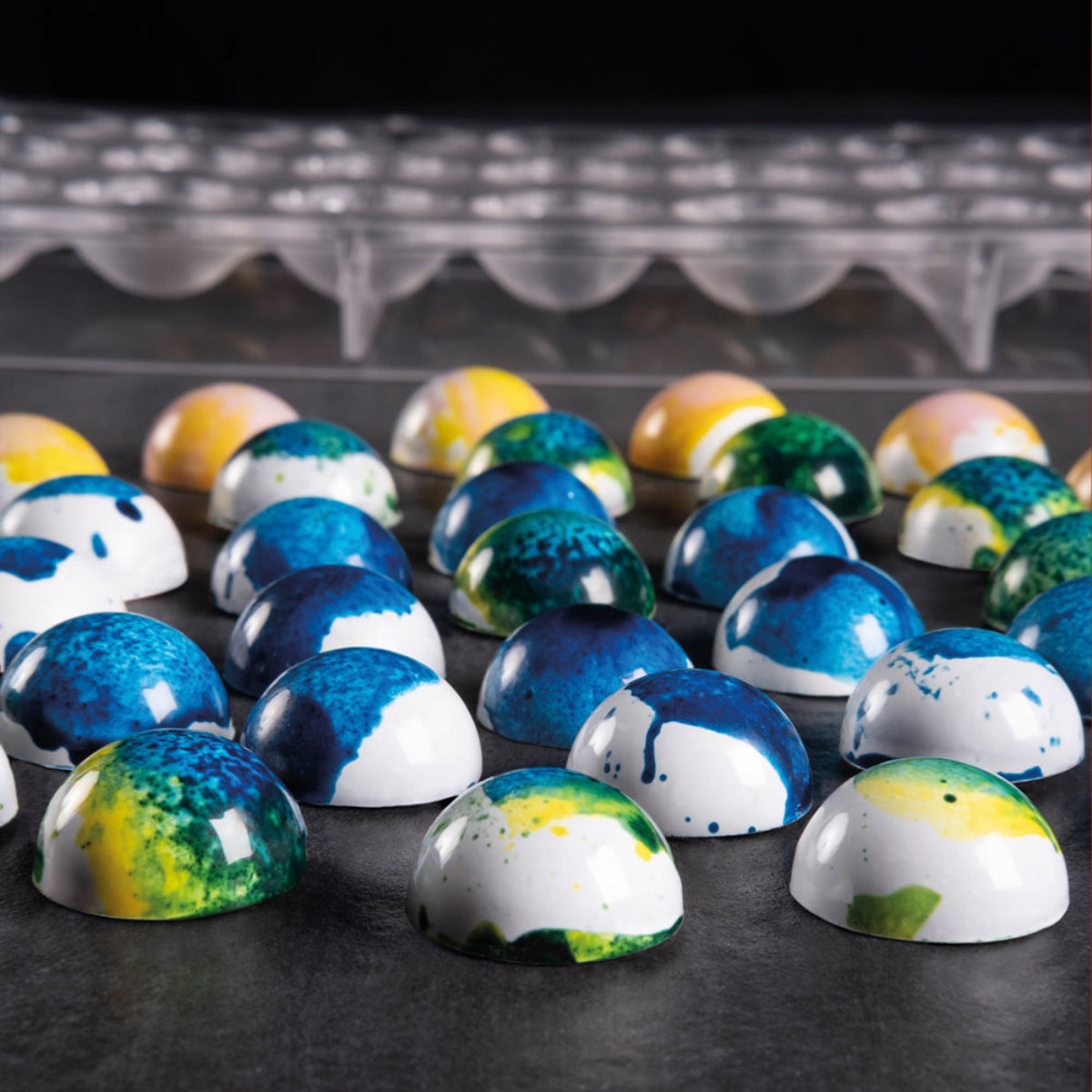

- Achieving proper viscosity for subsequent processes like tempering and molding

The Importance of Chocolate Conching in Chocolate Premium Flavor

Conching stands as the most crucial step in chocolate manufacturing, transforming rough, bitter cocoa mass into the smooth, flavorful chocolate we know and love. This process is considered critical for two fundamental reasons that directly impact your chocolate's quality and consumer experience.

- Texture transformation - Creates uniform particle coating with cocoa butter for smooth mouthfeel

- Flavor refinement - Removes harsh volatile acids while developing complex flavor compounds

- Viscosity control - Determines flow properties for molding, enrobing, and coating applications

- Moisture removal - Eliminates residual water that affects shelf life and stability

The dual challenge of conching: This process must carefully balance removing unwanted compounds (like acetic acid from fermentation) while preserving and enhancing desirable aromatic molecules that give chocolate its distinctive character. Think of it like a perfume—too much agitation and time can actually strip away the very flavors you want to preserve.

Without proper conching, even the finest cocoa beans would produce chocolate with unpleasant astringent notes, poor texture, and inadequate shelf stability—making this process absolutely essential for any quality chocolate production

Equipment Used for Conching Chocolate

Traditional Conches

The original conche designed by Lindt was a granite trough with a granite roller that moved back and forth, physically working the chocolate. These early devices were limited in capacity and required significant time and energy, but they established the foundation for chocolate as we know it today.

Traditional longitudinal conches still exist and are prized by some artisanal chocolate makers for their gentle action and the quality of chocolate they produce.

Modern Conching Machines

Today's chocolate manufacturers use a variety of modern conching equipment:

- Rotary conches: Featuring rotating arms or blades in a cylindrical vessel, these are common in medium-scale production.

- Ball mills: These use steel balls to provide additional grinding during the conching process.

- Continuous conches: Used in large-scale production, these allow chocolate to flow through a series of chambers, completing the conching process in less time.

- Vertical conches: These take up less floor space and often integrate multiple stages of chocolate processing.

How Conching Affects Chocolate Quality

Flavor Development

One of the most important aspects of conching chocolate is flavor development. During conching:

- Unwanted flavors decrease: Acetic acid and other volatile compounds that contribute harsh, acidic notes evaporate.

- Desirable flavors emerge: Through oxidation and other chemical changes, more complex and pleasant flavor compounds develop.

- Flavor harmonization: The extended mixing allows flavors to blend and harmonize into a cohesive profile.

Master chocolate makers can adjust conching parameters to highlight specific flavor notes or achieve particular profiles. The conching time and temperature significantly impact whether fruity, floral, nutty, or caramel notes predominate in the final chocolate.

Texture Improvement

The texture transformation during conching is just as dramatic as the flavor development:

- Particle coating: Each tiny particle of cocoa solids and sugar becomes completely coated with cocoa butter.

- Friction reduction: This coating reduces friction between particles, creating the smooth mouthfeel of fine chocolate.

- Viscosity control: Conching helps achieve the proper viscosity for the intended application, whether it's coating, molding, or another use.

This textural refinement is what creates chocolate that melts smoothly on your tongue rather than feeling gritty or grainy.

Reduction of Acidity and Bitterness

Raw cocoa has naturally occurring acids and compounds that can taste harsh, bitter, or astringent. Conching helps to:

- Evaporate volatile acids

- Reduce perception of bitterness

- Round out sharp flavor edges

- Create a more balanced flavor profile

This is why properly conched chocolate has a smooth, rounded flavor even when using high percentages of cocoa.

Home Conching: Is it Possible?

For chocolate enthusiasts wondering if they can conche chocolate at home, the answer is: yes, but with limitations.

True conching requires specialized equipment that's rarely practical for home use. However, some alternatives exist:

- Melanger/wet grinders: Devices originally designed for Indian cuisine (like making dosa batter) have been adapted by craft chocolate makers. Models like the Premier Wonder Grinder or Spectra Stone Grinder can process small batches of chocolate.

- Modified food processors: With significant limitations, some home chocolate makers use extended processing in food processors to achieve a partial conching effect.

- Specialized home chocolate machines: A few companies now make small-scale machines specifically for home chocolate making that incorporate conching functions.

These methods can produce reasonable results for hobbyists, but they generally can't match the refinement of professionally conched chocolate.

How To Know if Chocolate is Well-Conched

How can you tell if the chocolate you're buying has been properly conched? Look for these indicators:

- Smooth texture: When you let it melt on your tongue, there should be no grittiness or graininess.

- Glossy appearance: Well-conched chocolate has a uniform sheen when properly tempered.

- Complex aroma: The chocolate should have a deep, nuanced aroma without sharp acidic notes.

- Balanced flavor: The taste should be harmonious without extreme bitterness or acidity.

- Clean melt: The chocolate should melt evenly and smoothly in your mouth.

Premium chocolate makers often mention their conching times on packaging as a mark of quality—with longer times generally indicating greater care and refinement.

FAQ

How long does conching chocolate typically take?

Conching times vary widely depending on the type of chocolate and quality level:

- Commercial-grade chocolate: 6-16 hours

- Premium chocolate: 24-72 hours

- Ultra-premium or specialty chocolate: 72+ hours (some artisanal makers conche for up to 96 hours)

Does all chocolate undergo conching?

Nearly all modern commercial chocolate undergoes some form of conching, though the time and intensity vary greatly. Mass-produced, lower-quality chocolates might receive minimal conching, while premium chocolates receive extended conching. The only chocolate that might not be conched would be some extremely rustic, traditional products or experimental "raw" chocolates.

Does conching chocolate affect its nutritional value?

Conching has minimal impact on the macro-nutritional components of chocolate (fats, carbohydrates, proteins). However, some studies suggest that extended conching may reduce the levels of certain polyphenols and antioxidants in chocolate. This is a trade-off between flavor quality and preserving every bit of the original antioxidant content.

Can you over-conch chocolate?

Yes, it is possible to over-conch chocolate. Signs of over-conching include:

- Loss of distinctive origin flavor notes

- Development of "flat" taste profile

- Excessive oxidation of cocoa butter leading to off-flavors

- Unwanted texture changes

Master chocolate makers carefully monitor the process to avoid this.

What temperature is used for conching chocolate?

Conching temperatures typically range from 45°C to 85°C (113°F to 185°F), with different phases often using different temperatures:

- Lower temperatures (45-60°C) often used for flavor development phases

- Higher temperatures (70-85°C) used for moisture removal and viscosity adjustment

The specific temperatures are crucial to the outcome and are often closely guarded recipes.

Is chocolate conching the same worldwide?

While the basic principles of conching are universal, there are regional variations:

- European tradition often emphasizes longer conching times

- American commercial chocolate typically uses shorter conching periods

- Some Asian chocolate makers integrate local spices during the conching process

These variations contribute to the distinct character of chocolates from different regions.

Conclusion

Conching chocolate represents the transformative phase where rough chocolate mass becomes the smooth, flavorful product we love. This process, invented over 140 years ago, remains essential to quality chocolate production today.

The time, technique, and equipment used for conching directly impact the final chocolate's flavor profile, texture, and overall quality. While technology has evolved, the fundamental principles that Rodolphe Lindt discovered continue to guide chocolate makers worldwide.

Whether you're a chocolate connoisseur appreciating the nuances of different conching techniques or simply someone who enjoys a smooth piece of chocolate, understanding this process adds another dimension to your chocolate experience. The next time you savor a piece of fine chocolate that melts perfectly on your tongue and delivers a complex flavor journey, you'll know that conching played a crucial role in creating that moment of pleasure.

For those interested in chocolate making or working with quality chocolate products in their home or business, visit Zucchero Canada for a selection of premium chocolate supplies.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.