Developing a new chocolate product requires a careful blend of culinary artistry, market research, and technical expertise. Whether you're an established chocolatier looking to expand your product line or an entrepreneur entering the confectionery market, this comprehensive guide will walk you through the essential stages of chocolate product development.

Understanding the Chocolate Market Landscape

Before diving into product development, it's crucial to understand the current chocolate market. The global chocolate industry continues to evolve, with consumers increasingly seeking premium, ethically sourced, and innovative flavor profiles. Health-conscious alternatives like sugar-free, organic, and functional chocolates (enriched with superfoods or adaptogens) have gained significant traction in recent years.

Market research reveals that while traditional milk and dark chocolates remain staples, there's growing interest in single-origin chocolates, bean-to-bar products, and unique flavor combinations that tell a story. Sustainability credentials and transparent sourcing have become key purchasing factors for many consumers, particularly millennials and Gen Z.

The Chocolate Product Development Process

Step 1: Concept Development and Market Research

Begin by identifying a gap in the market or a unique selling proposition for your chocolate product. This could be an innovative flavor combination, a health benefit, sustainable sourcing, or a novel presentation format.

Conduct thorough market research by:

-

Analyzing competitor products and their positioning

-

Identifying target consumer segments and their preferences

-

Studying market trends in ingredients, packaging, and pricing

-

Gathering consumer feedback through surveys or focus groups

This research will help refine your concept and ensure there's genuine market demand for your chocolate innovation.

Step 2: Recipe Development and Formulation

The heart of chocolate product development lies in perfecting the recipe. This typically involves:

Creating a base chocolate formulation with the right balance of cocoa solids, cocoa butter, sugar, milk solids (for milk chocolate), and emulsifiers. Each component affects flavor, mouthfeel, and shelf stability.

Experimenting with additional ingredients such as nuts, fruits, spices, or functional additives while ensuring they complement the chocolate base rather than overwhelming it.

Testing different cocoa bean varieties, origins, and roasting profiles to achieve the desired flavor notes—fruity, nutty, earthy, or floral.

Working with food scientists or chocolatiers to address technical considerations like tempering behavior, bloom resistance, and texture stability.

Recipe development is an iterative process requiring multiple adjustments and taste tests before finalizing the formulation.

Step 3: Sourcing and Supply Chain Development

Quality chocolate begins with quality ingredients. Establish relationships with reliable suppliers for:

-

Cocoa beans or couverture chocolate

-

Sweeteners (sugar, alternative sweeteners)

-

Dairy ingredients (for milk chocolates)

-

Additional flavorings and inclusions

-

Emulsifiers and stabilizers

Consider ethical sourcing practices and certifications that align with your brand values, such as Fair Trade, Rainforest Alliance, or direct trade relationships with cocoa farmers.

Step 4: Production Process Development

Translate your kitchen-scale recipe to commercial production by:

-

Determining the appropriate manufacturing processes (bean-to-bar vs. using couverture)

-

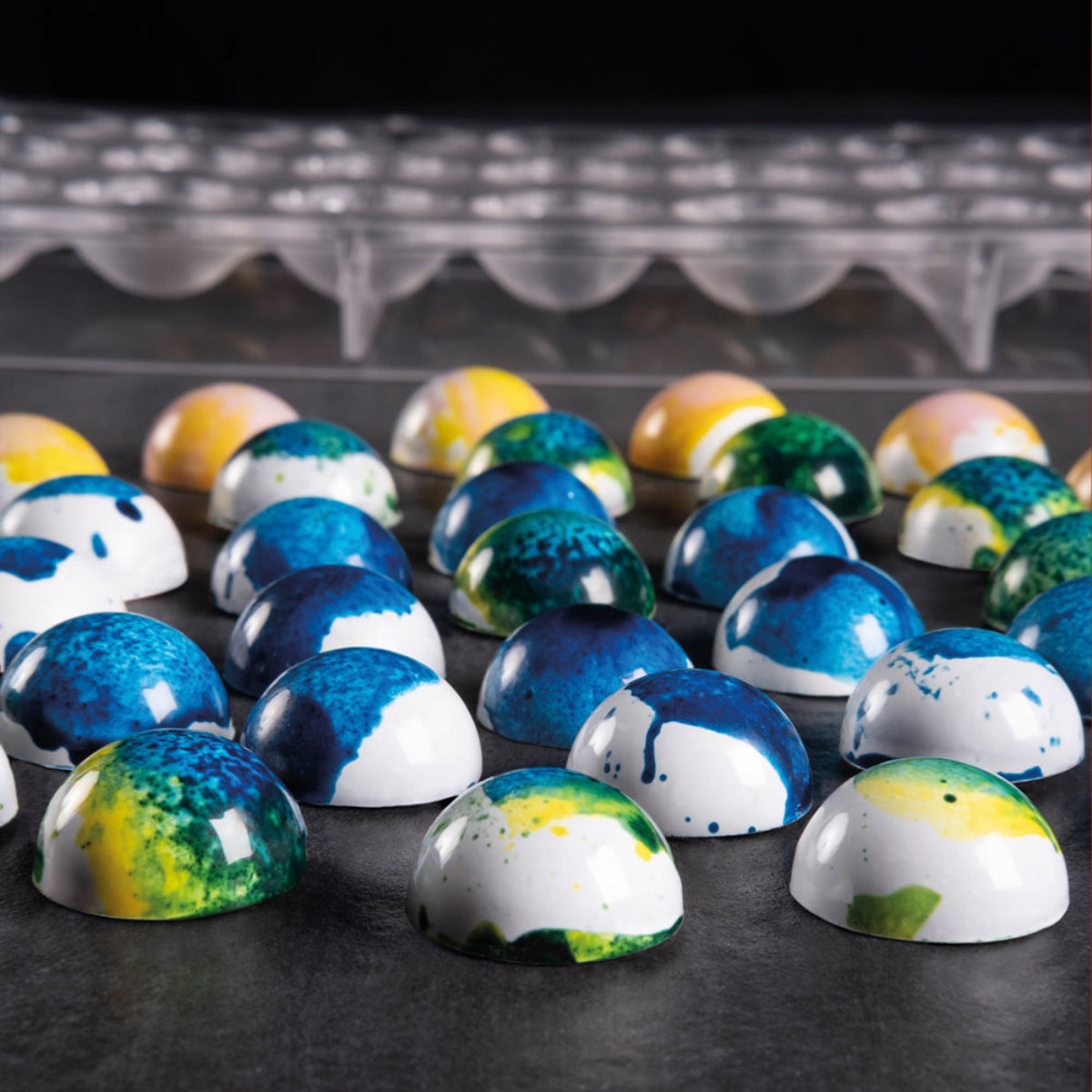

Identifying necessary equipment for mixing, conching, tempering, molding, and packaging

-

Establishing standard operating procedures for consistent quality

-

Developing quality control checkpoints throughout production

-

Creating scaling protocols as production volume increases

The production process must balance artisanal quality with operational efficiency to ensure profitability.

Step 5: Packaging Design and Development

Packaging plays a crucial role in chocolate product success, serving both functional and marketing purposes:

-

Design packaging that preserves freshness and prevents damage

-

Create visually appealing packaging that communicates your brand story

-

Include required nutritional information and allergen warnings

-

Consider sustainability in packaging materials and design

-

Ensure packaging is practical for retail display and consumer use

Collaborate with packaging designers who understand food protection requirements while creating eye-catching designs that stand out on shelves.

Step 6: Regulatory Compliance and Food Safety

Chocolate products must meet relevant food safety standards and regulations:

-

Obtain necessary food production licenses and certifications

-

Ensure facilities meet health department requirements

-

Implement HACCP (Hazard Analysis Critical Control Points) protocols

-

Conduct nutritional analysis and develop accurate labeling

-

Address allergen control and cross-contamination prevention

-

Determine shelf life through stability testing

Working with food safety consultants can help navigate these complex requirements efficiently.

Step 7: Market Testing and Feedback Collection

Before full-scale launch, test your chocolate product with real consumers:

-

Produce small batches for sampling events

-

Conduct structured taste tests with target consumers

-

Gather feedback on flavor, texture, packaging, and pricing

-

Test in limited retail environments to gauge sales performance

-

Make final adjustments based on consumer response

This valuable feedback can help refine your product before investing in large-scale production.

Step 8: Marketing Strategy and Launch Planning

Develop a comprehensive marketing strategy that includes:

-

Brand positioning and key messaging

-

Pricing strategy that reflects quality while ensuring profitability

-

Distribution channels (specialty stores, online, mainstream retail)

-

Promotional activities (sampling, social media, partnerships)

-

Launch timeline and rollout plan

Your marketing should emphasize your chocolate's unique selling points, whether that's exceptional flavor, ethical sourcing, health benefits, or innovative ingredients.

Step 9: Launch and Post-Launch Evaluation

After launching your chocolate product:

-

Monitor initial sales performance across channels

-

Continue collecting customer feedback

-

Track production costs and profit margins

-

Identify opportunities for product line extensions

-

Make adjustments to marketing or distribution as needed

The post-launch period is critical for making quick adjustments that can determine long-term success.

Challenges and Considerations in Chocolate Product Development

Developing chocolate products presents unique challenges:

-

Temperature sensitivity requires careful handling throughout production and distribution

-

Seasonal demand fluctuations affect production planning and inventory management

-

Commodity price volatility, particularly for cocoa beans, impacts cost stability

-

Increasing consumer expectations for sustainability and ethical sourcing

-

Competition from both artisanal and mass-market producers

Successful chocolate product developers anticipate these challenges and build flexibility into their business models.

By following this comprehensive development process and remaining responsive to market feedback, you can create chocolate products that delight consumers, stand out in a competitive marketplace, and build a sustainable confectionery business.

Remember that chocolate product development is both an art and a science—balancing creativity with technical precision, and market awareness with authentic passion for creating exceptional chocolate experiences.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.